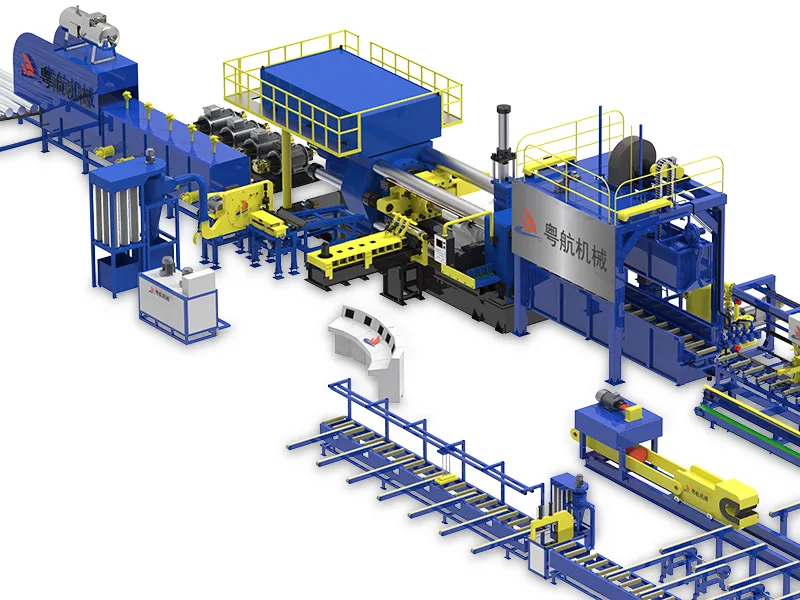

Our fully automatic aluminum profile production line integrates advanced industrial control equipment with industrial internet technology to facilitate efficient data exchange across all equipment involved in the extrusion process. Through intelligent software, the operation and storage data of the entire production line are uploaded to a centralized data processing center.

- Aluminum billets are placed on the rack of the long rod heating furnace, heated to approximately 480°C, and kept at this temperature for one hour.

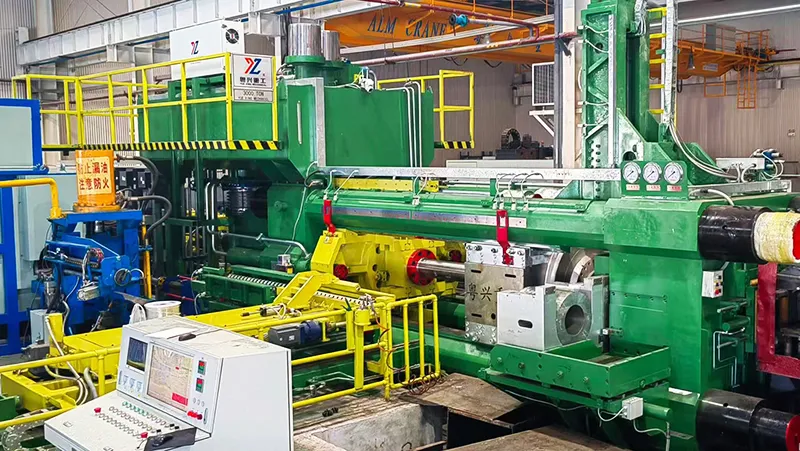

- The billets are then cut and fed into the raw material inlet of the extrusion press. The extrusion press shapes the heated billets into various aluminum alloy profiles using molds of different specifications.

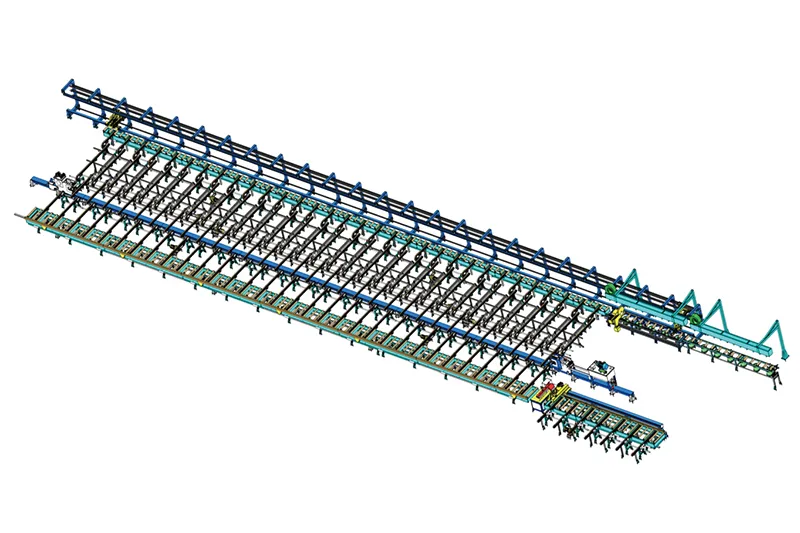

- The profiles are air-cooled and transported by the puller for length determination and alignment.

- The aligned profiles are moved to the stretching machine for straightening.

- The straightened profiles are transferred to the cut-to-length table, where they are cut to the desired length.

- Finally, the finished aluminum profiles are packed and transported to the aging furnace trolley for treatment, achieving their intended properties and completing the processing.

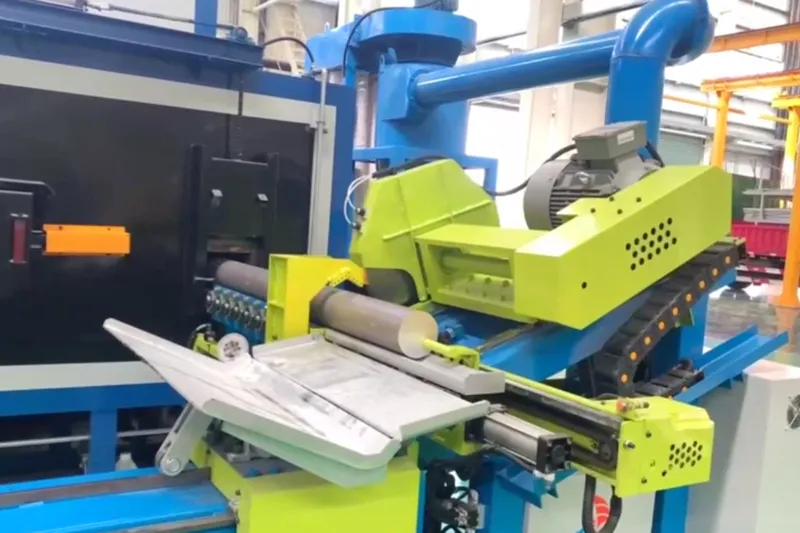

We provide complete solutions for your aluminum extrusion projects, as well as supporting equipment for your aluminum extrusion lines. Our aluminum extrusion equipment includes extrusion presses, intelligent extrusion pullers, three-head extrusion pullers, hot log saws, and more. Customers looking for a total package solution to meet their specifications can rely on our comprehensive turnkey systems, which combine precision, efficiency, and customization.

-

- Long-Stroke Aluminum Extrusion Press (780-1100T) The electric-hydraulic hybrid extrusion press is designed for speed, precision, and stability. Driven by a servo motor, it ensures faster and more accurate feeding of aluminum billets into the extrusion press. The main structure features a pre-stressed composite frame, which effectively reduces the elastic deformation of guide posts and enhances aluminum extrusion precision and stability. Learn More

-

- Short-Stroke Aluminum Extrusion Press (1250-7500T) The short-stroke aluminum extrusion press takes productivity to the next level by reducing non-extrusion time and delivering improved precision in aluminum extrusion. With its high-capacity capabilities, this advanced press not only boosts efficiency but also provides cost-effective and eco-friendly solutions to meet the demands of modern aluminum profile production. Learn More