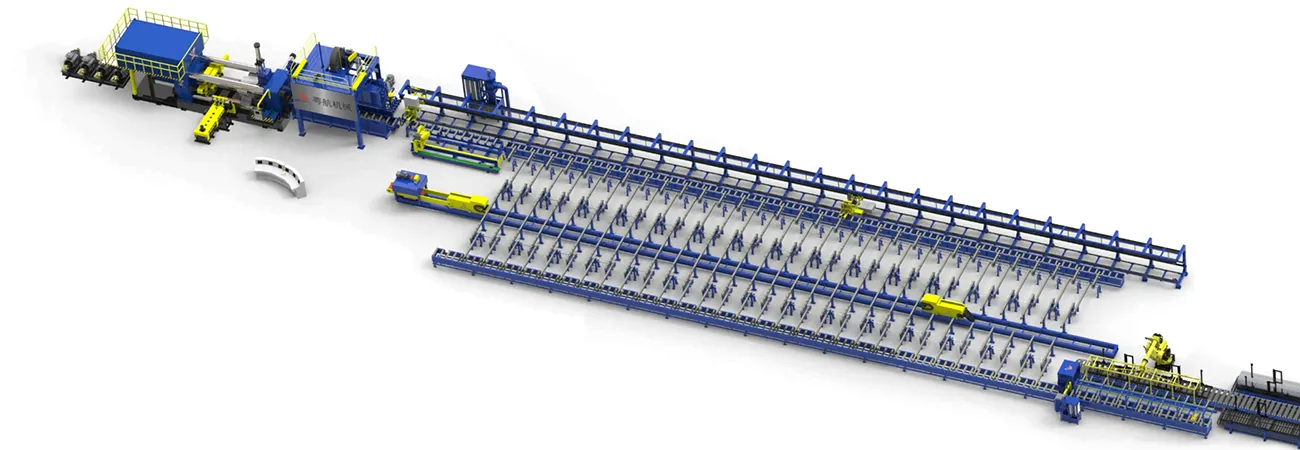

With each aluminum extrusion system or equipment we offer, we deliver high-quality products and reliable services. Our comprehensive solutions are thoughtfully designed to address every stage of the production process, ensuring exceptional precision, enhanced efficiency, and seamless integration to meet the diverse and demanding requirements of modern aluminum extrusion applications.

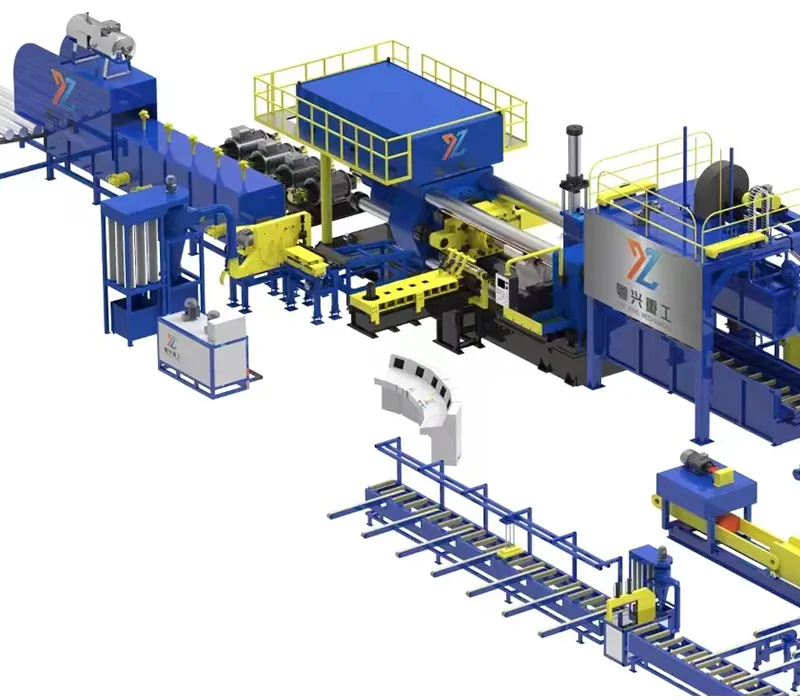

We provide customized layout design solutions for aluminum extrusion production lines tailored to your specific needs and site conditions, ensuring optimal efficiency and practicality in your production line setup.

- Safety protection features

Comprehensive safety measures such as emergency stop buttons, protective barriers, and safety light curtains are included to safeguard operators during equipment operation. - Electrical safety

The electrical system adheres to relevant electrical safety standards, featuring proper grounding, insulation, and overload protection to prevent electrical hazards. - Noise and emission control

Equipment operation complies with industrial noise emission standards specific to your region. The emissions of waste gases, wastewater, and solid waste generated during production are controlled to minimize environmental impact.

Our focus is on designing aluminum profile extrusion lines that not only meet your operational requirements but also prioritize safety, environmental compliance, and efficiency.

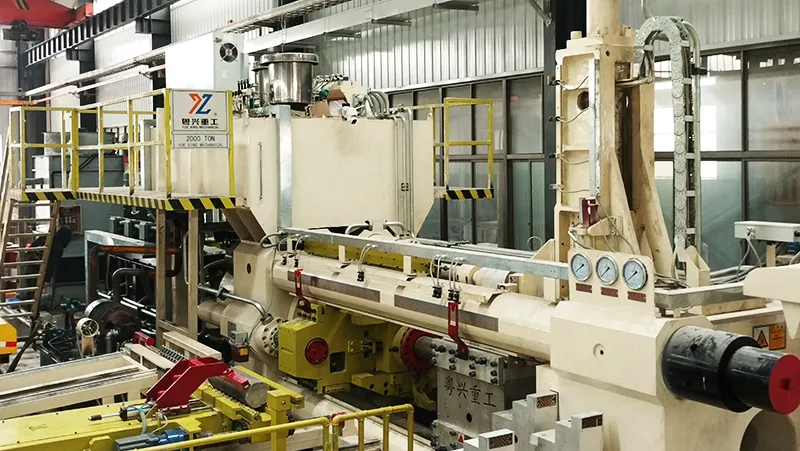

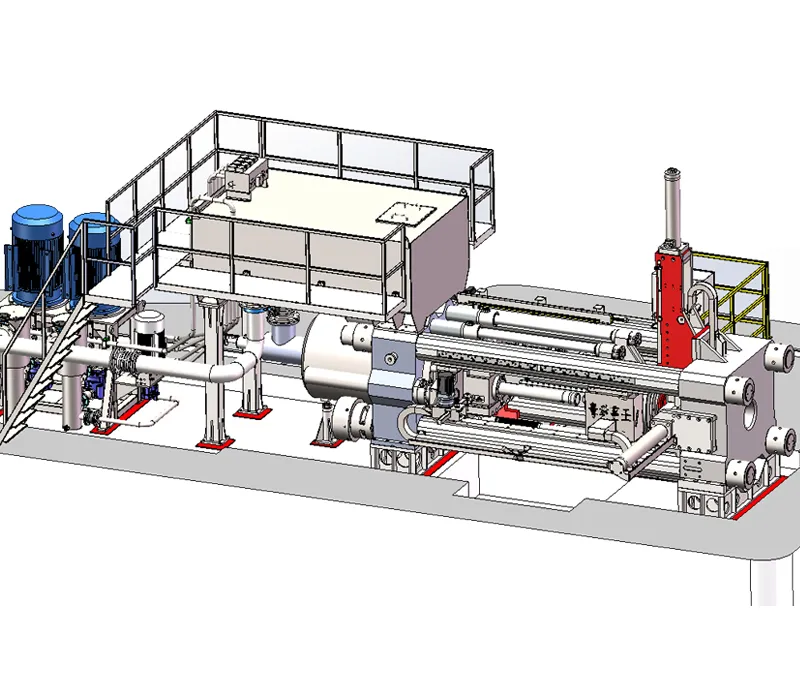

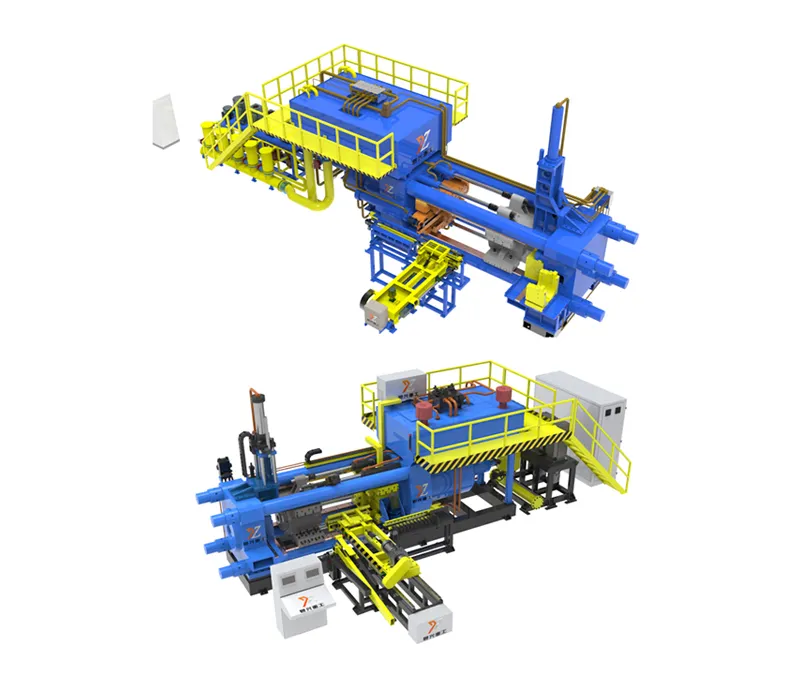

We provide aluminum extrusion press equipment tailored to meet our clients' production needs and product specifications, ensuring optimal performance and quality.

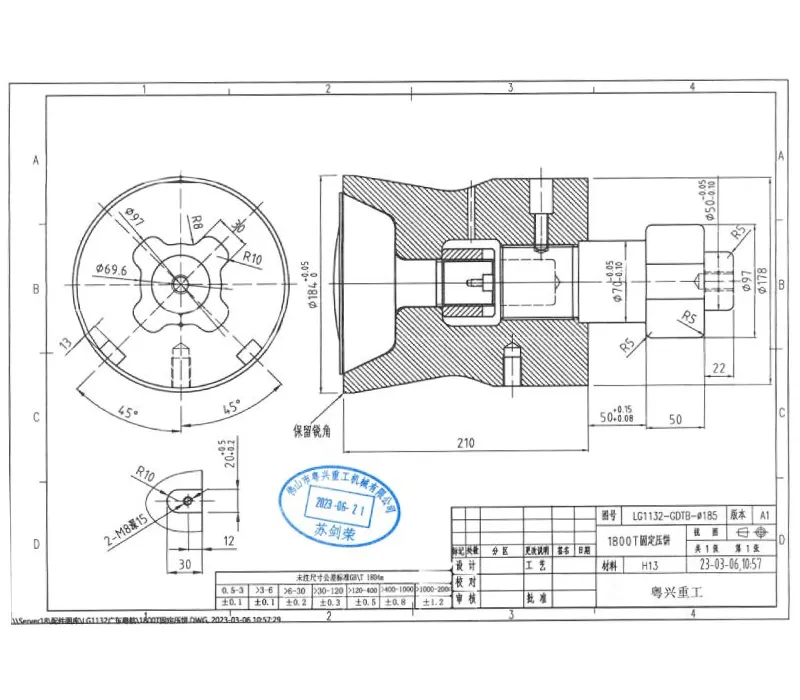

- Pressure and tonnage

Equipment is configured based on the diameter of aluminum billets. For example, an 80-85mm billet corresponds to a 500T press, while a 127mm billet matches a 1000T press. This ensures sufficient pressure for effective aluminum extrusion and forming. - Speed and efficiency

Equipment is customized to meet specific production requirements, such as idle cycle time and extrusion efficiency. For instance, for a client requiring a 12.65-second idle cycle and 5 seconds per profile extrusion, we designed a tailored solution to meet these needs. - Temperature control precision

Precise control of heating and insulation temperatures is maintained for the extrusion cylinder (400℃-460℃) and dies (420℃-480℃) to ensure uniform material structure and performance. - Mechanical strength and stability

All equipment features robust mechanical structures capable of withstanding high extrusion pressures, ensuring long-term reliability and safety while minimizing product defects caused by deformation or vibrations.

Our focus is on designing aluminum profile extrusion lines that not only meet your operational requirements but also prioritize safety, environmental compliance, and efficiency.