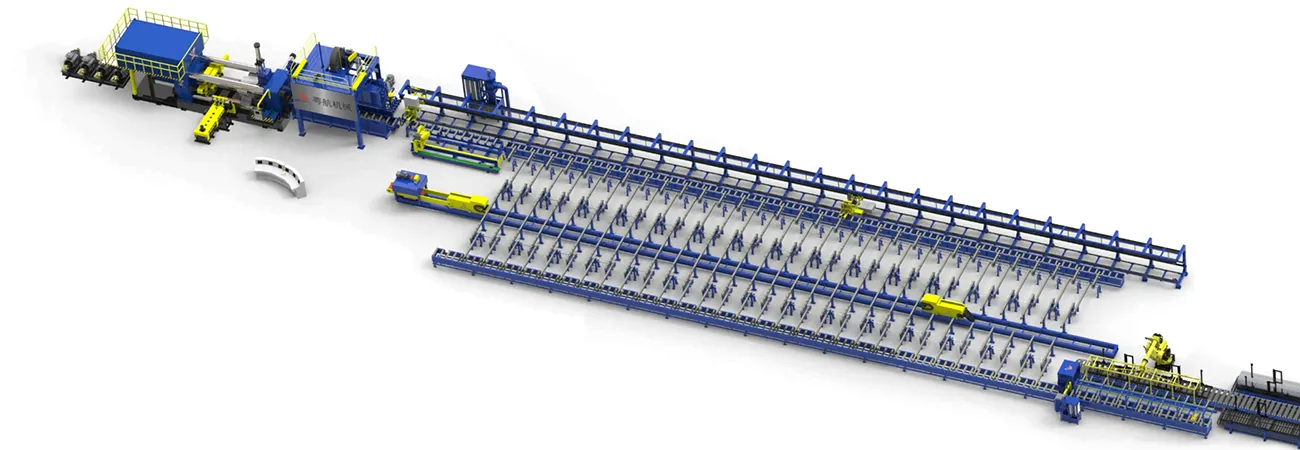

Our aluminum extrusion equipment includes extrusion presses, intelligent extrusion pullers, three-head extrusion pullers, hot log saws, and more. Customers looking for a total package solution to meet their specifications can rely on our comprehensive turnkey systems, which combine precision, efficiency, and customization.

Our extrusion press models range from 780 tons to 7500 tons, offering dozens of machine types. Each press is equipped with a unique, advanced oil-electric control system and an intelligent digital control and monitoring system. By using original imported components, our aluminum extrusion equipment ensures greater stability during production, higher extrusion precision, and shorter non-extrusion times.

With an oil-electric hybrid design, our extrusion presses save 20%-40% more energy compared to traditional models, significantly improving aluminum profile production efficiency while reducing energy consumption.

-

- Aluminum Extrusion Press The electric-hydraulic hybrid extrusion press is designed for speed, precision, and stability. Driven by a servo motor, it ensures faster and more accurate feeding of aluminum billets into the extrusion press. The main structure features a pre-stressed composite frame, which effectively reduces the elastic deformation of guide posts and enhances aluminum extrusion precision and stability. Learn More

-

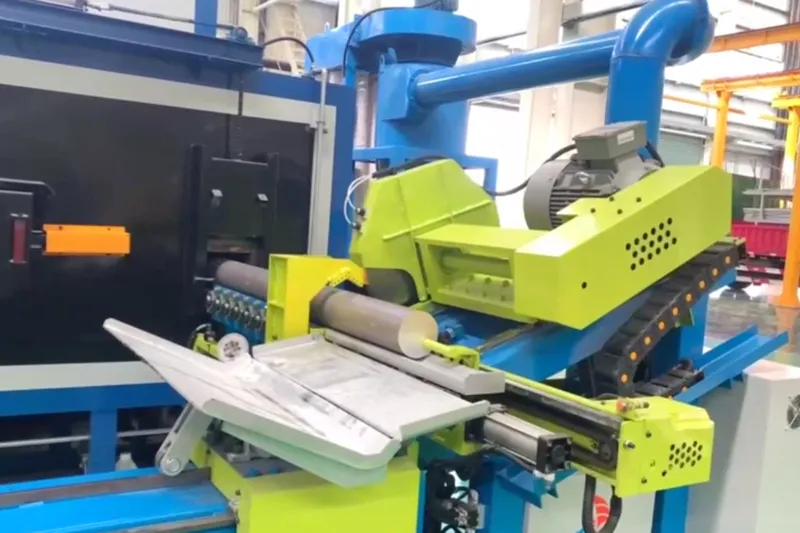

- Aluminum Extrusion Puller The extrusion puller system integrates two puller heads (P1/P2) and one saw, capable of running continuously for 24 hours with fully automated operations, eliminating the need for manual intervention. Controlled by Siemens’ system, it ensures stability for the reciprocal motion of carriages, avoiding vibration marks. Designed for extrusion speeds of 60-72 meters/min and presses ranging from 3600T to 7500T, our all-electric, fully servo-driven three-head puller supports press capacities from 400T to 5000T. Learn More

-

- Quench System Aluminum profile quench system with air and water cooling options for enhanced profile hardness. Features include adjustable cooling settings, efficient operation, and durable components. Learn More

-

- Hot Log Saw The hot log saw acts as a connecting device between the aluminum billet heating furnace and the extrusion press. It is a widely used auxiliary component in aluminum extrusion production lines. Designed for accurate length cutting and smooth cross-section finishes, this hot log saw optimizes billet utilization and improves aluminum profile production efficiency. Learn More

-

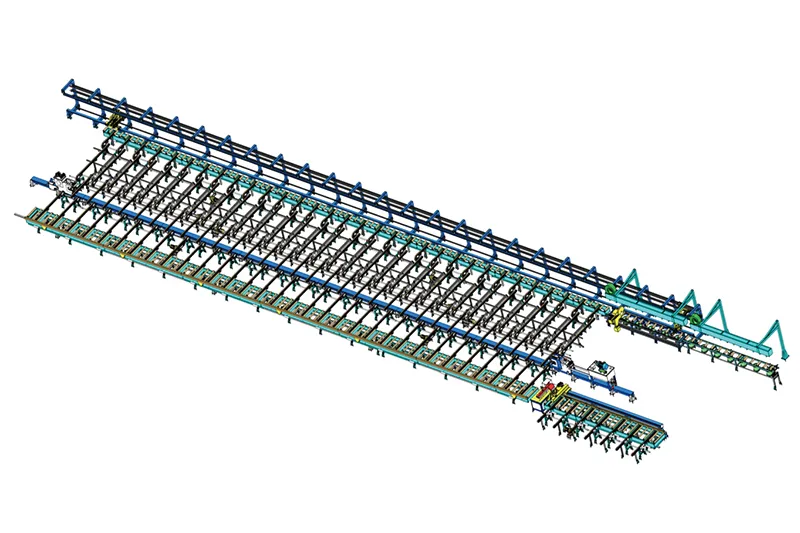

- Cooling Table The cooling table is designed for aluminum extrusion equipment of 1650T and above or for processing high-precision profiles. It features up to 500T hydraulic straightening equipment and employs a walking-style conveyor system to prevent surface scratches on profiles, a common issue with traditional cooling beds. The surface of the equipment uses high-temperature-resistant Kevlar felt, offering superior heat adaptability. Learn More

-

- Single Billet Furnace The single billet jet-type heating furnace integrates thermal, mechanical, and automated control technologies, providing a complete heating solution to the desired temperature for aluminum extrusion. This heating furnace ensures energy efficiency, precise temperature control, and optimal performance for high-quality aluminum extrusion processes. Learn More

-

- Multi-Billet Furnace The fully automated, energy-efficient multi-billet heating furnace is designed to provide uniform heating for aluminum billets. It comprises an aluminum billet feeding system, furnace body, hot shearing machine, combustion system, and PLC control system. Learn More

-

- Die Oven The die oven uses induction electric heating based on electromagnetic principles. Compared to traditional heating methods, this furnace produces fewer pollutants during the heating process, making it more environmentally friendly. It ensures uniform heating of the entire die, reducing deformation caused by temperature differences and enhancing the quality and lifespan of the die. Learn More

-

- Automatic Stretcher The aluminum extrusion stretcher straightens bent aluminum profiles to high precision, ensuring the final straightness meets strict quality standards, typically within 1-3mm per meter. With features like automatic feeding, straightening, and fixed-length cutting, it minimizes manual intervention, boosts production efficiency, reduces labor intensity, and eliminates human error for efficient and stable aluminum profile production. Learn More

-

- Age Oven (Annealing Oven) The age oven uses a hot air circulation system to ensure uniform heat distribution within the chamber, improving the consistency of aluminum profile aging treatment. Fans mounted on the top or sides of the furnace circulate heat generated by heating elements, ensuring every part of the aluminum profile is evenly heated. Some ovens are equipped with special air guide structures or baffles to optimize airflow and enhance temperature uniformity. Learn More