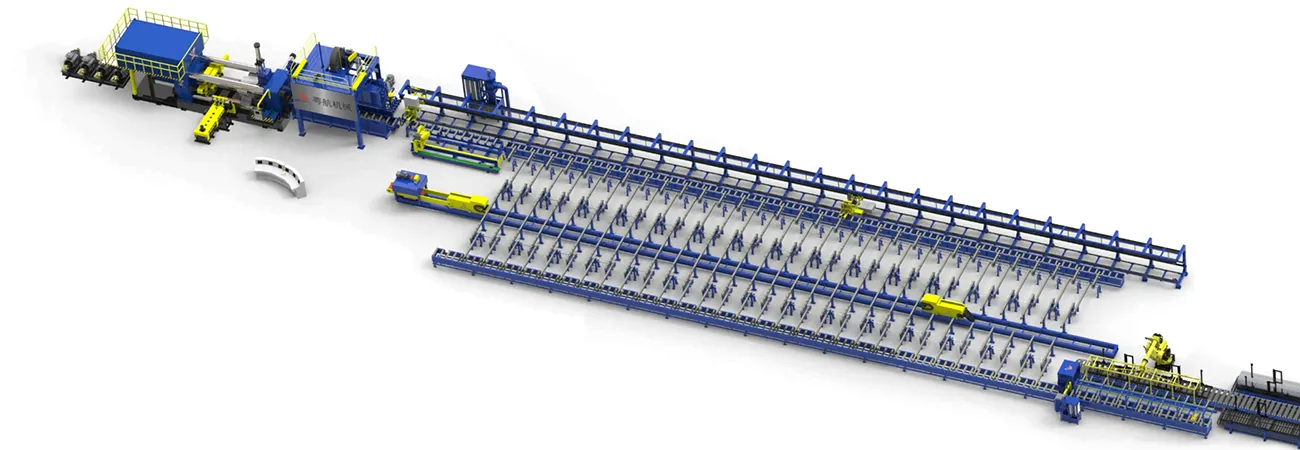

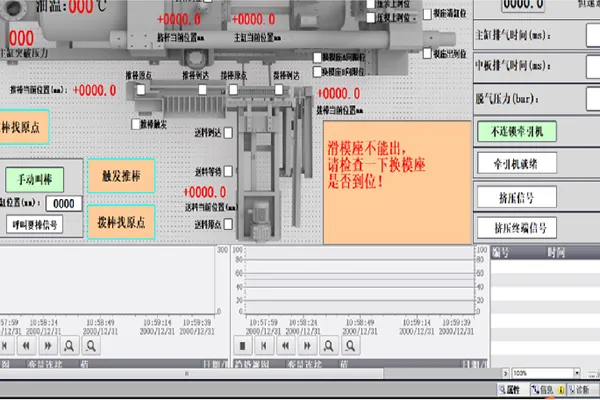

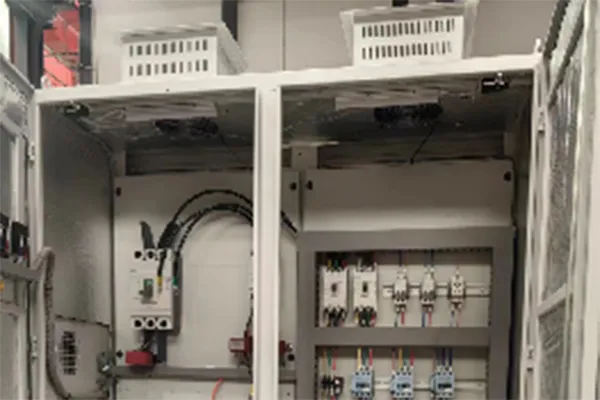

Our fully automatic aluminum profile production line integrates advanced industrial control equipment with industrial internet technology to facilitate efficient data exchange across all equipment involved in the extrusion process. Through intelligent software, the operation and storage data of the entire production line are uploaded to a centralized data processing center. This approach accelerates the extrusion process, improves precision, and simplifies maintenance, ultimately rationalizing the aluminum profile extrusion procedure and maximizing efficiency.

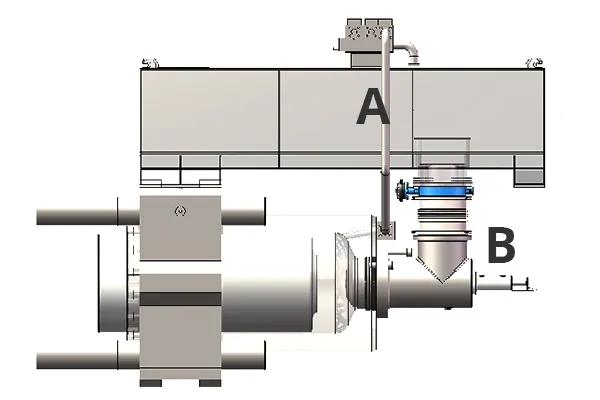

- Aluminum billets are placed on the rack of the long rod heating furnace, heated to approximately 480°C, and kept at this temperature for one hour.

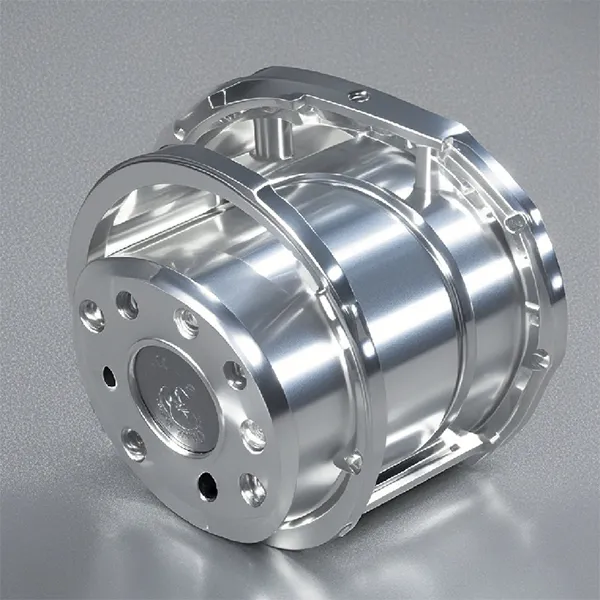

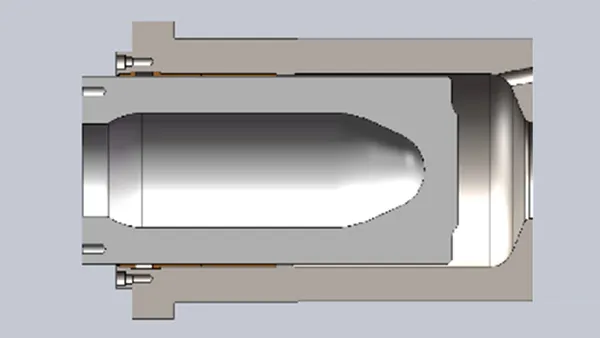

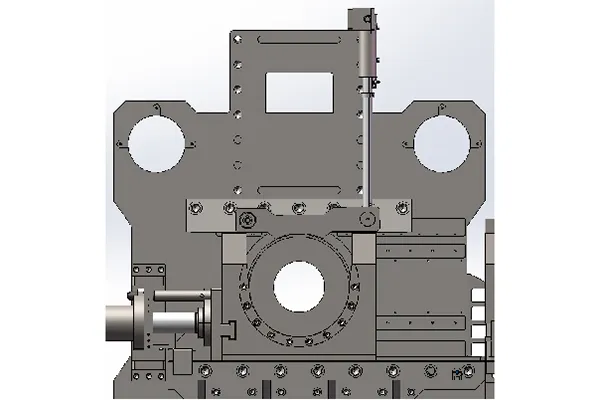

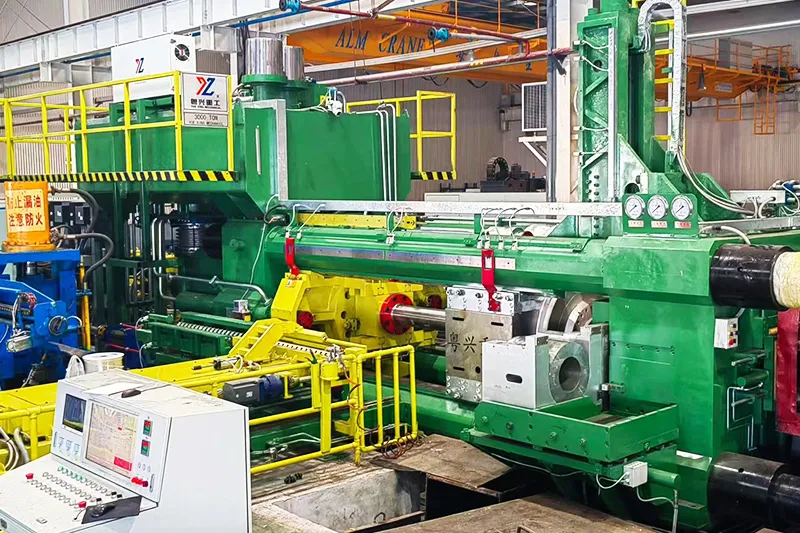

- The billets are then cut and fed into the raw material inlet of the extrusion press. The extrusion press shapes the heated billets into various aluminum alloy profiles using molds of different specifications.

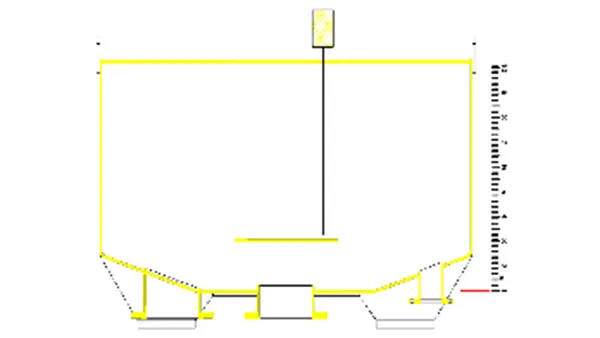

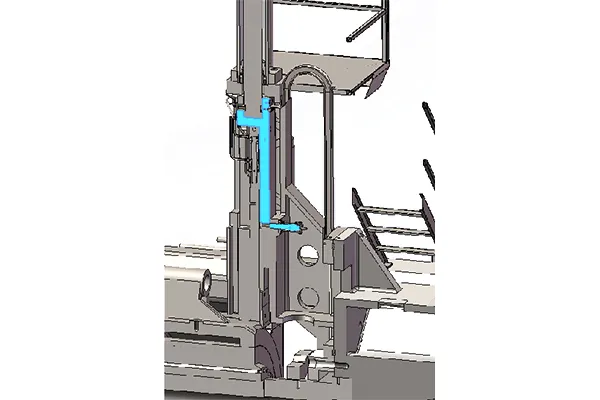

- The profiles are air-cooled and transported by the puller for length determination and alignment.

- The aligned profiles are moved to the stretching machine for straightening.

- The straightened profiles are transferred to the cut-to-length table, where they are cut to the desired length.

- Finally, the finished aluminum profiles are packed and transported to the aging furnace trolley for treatment, achieving their intended properties and completing the processing.