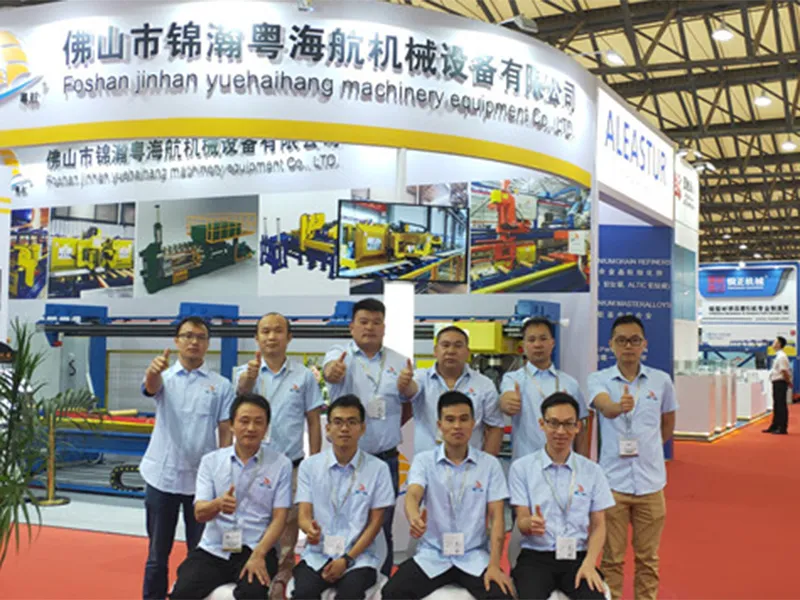

Established in 2013, Foshan Yuexing Machinery Equipment company is located in Nanhai, Guangdong, China's renowned hub for aluminum profile manufacturing and innovation. We are a professional enterprise specializing in the research, development, manufacturing, and sales of automated equipment for aluminum profile extrusion lines.

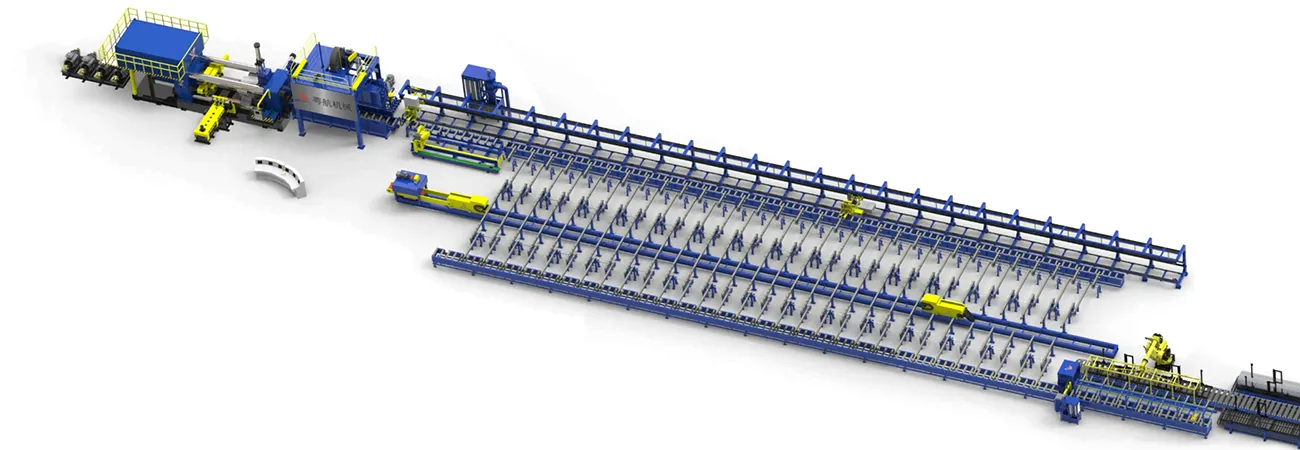

Yuexing is dedicated to providing turnkey solutions for complete aluminum extrusion lines, offering aluminum extrusion presses along with a wide range of auxiliary equipment such as quench systems, pullers, hot log saws, and die ovens. With over a decade of experience, we deliver customized solutions tailored to meet the specific needs of our clients, ensuring efficiency, precision, and sustainability in aluminum profile production.

Our technology incorporates advanced systems like oil-electric hybrid designs and Siemens-powered automation, enabling better energy efficiency and precision. With a significant global presence, our solutions have been adopted by over 6,000 enterprises across 170 countries. Holding 60% of the domestic market share for intelligent puller equipment, we are recognized for delivering quality and reliability. Our energy-saving designs reduce power consumption by up to 30%, ensuring cost-effectiveness and sustainability. For optimal results, we offer professional support with on-site installation, commissioning, and technical assistance to ensure smooth and efficient integration into your aluminum extrusion production process.

Our extrusion presses, ranging from 780T to 7500T, feature advanced oil-electric hybrid control systems, intelligent digital monitoring, and imported components. These innovations enhance stability, extrusion precision, and efficiency while reducing non-extrusion time. Compared to traditional models, our oil-electric hybrid extrusion machines offer 20%-40% energy savings, providing an eco-friendly solution for modern production needs.

Our 5,000 square meter production facility is equipped with over 30 advanced machining and assembly devices, such as milling machines and wire-cutting equipment. This enables us to handle the processing, assembly, and testing of all extrusion production line equipment in-house, catering to diverse model specifications. Our technical team is composed of seasoned professionals from mechanical engineering institutions with more than two decades of hands-on experience in the aluminum extrusion industry.

Our commitment to innovation and quality has earned us recognition as a National High-Tech Enterprise, along with ISO9001 certification and EU CE safety certification. With a dedicated research and development base in Shishan Town, Foshan (a national-level high-tech zone), we have established deep collaborations with leading universities to co-develop intelligent, high-pressure, and energy-efficient aluminum extrusion presses. Holding over 100 national design and invention patents, we are at the forefront of technological innovation, striving to use science to reduce the planet's temperature by 1°C.

At Yuexing, we combine expertise, advanced technology, and an unwavering commitment to sustainability to deliver exceptional solutions for our customers worldwide.

Yuexing has established strong partnerships with leading domestic aluminum profile enterprises, including Fenglu Aluminum, Xingfa Aluminum Profiles, Weiye Aluminum Profiles, Wacang Aluminum, FoenAluminum (Fujian and Henan), Jinpeng Aluminum, Xinxiang Aluminum, Haomen Aluminum, Mingdi Group, and Hongda Aluminum, among others.

Our aluminum profile extrusion machines are also widely exported to over 20 countries, including regions in Central and Eastern Europe, the Middle East, and Southeast Asia, with over 500 pullers shipped internationally.

For every client, we provide comprehensive support, including on-site installation, production commissioning, lifetime tracking services, and free technical training for equipment maintenance and repair. At Yuexing, we are committed to delivering thoughtful and reliable after-sales service to ensure long-term customer satisfaction.

Our fully automatic aluminum profile production line integrates advanced industrial control equipment with industrial internet technology to facilitate efficient data exchange across all equipment involved in the extrusion process. Through intelligent software, the operation and storage data of the entire production line are uploaded to a centralized data processing center.