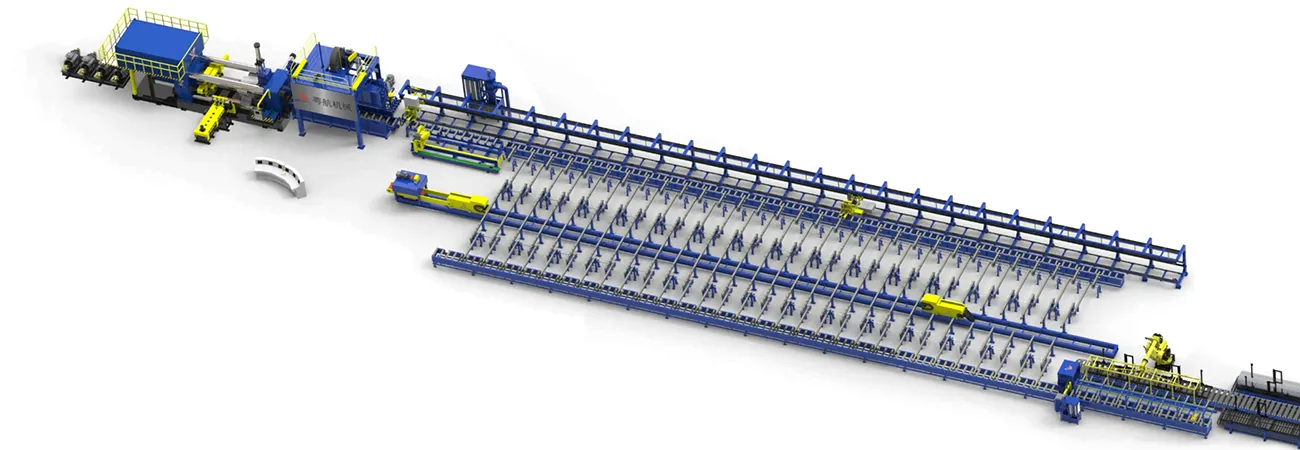

In the assembly workshop, various manufactured and processed components, including extrusion cylinders, extrusion rods, die holders, transmission devices, and hydraulic system components, are precisely assembled according to design specifications to form a complete aluminum extrusion press. This assembly process ensures that every machine meets strict performance and quality standards, delivering reliable and efficient solutions for aluminum extrusion production.

The commissioning workshop is responsible for the comprehensive testing and adjustment of assembled aluminum extrusion presses. This includes the mechanical transmission system, hydraulic system, and electrical control system to ensure seamless coordination among all systems and stable operation that meets the specified performance standards.

During and after assembly, the workshop conducts stringent quality inspections to verify the overall precision of the equipment. Checks include the installation accuracy of components, connection tightness, and system sealing to ensure the equipment complies with relevant quality standards and safety requirements.